Technical control of products is carried out in specialized premises equipped with the necessary testing equipment, instrumentation and instruments, as well as meeting the requirements of labor safety. The control and measuring devices and instruments used for verification undergo constant verification and certification in accredited metrological testing centers. Expand

Product quality control is carried out for compliance with the requirements of GOST 32131-2013, GOST 5717.1-2014, STO 42718591-001-2020, STO 42718591-002-2020, TR TS 005/2011 and includes:

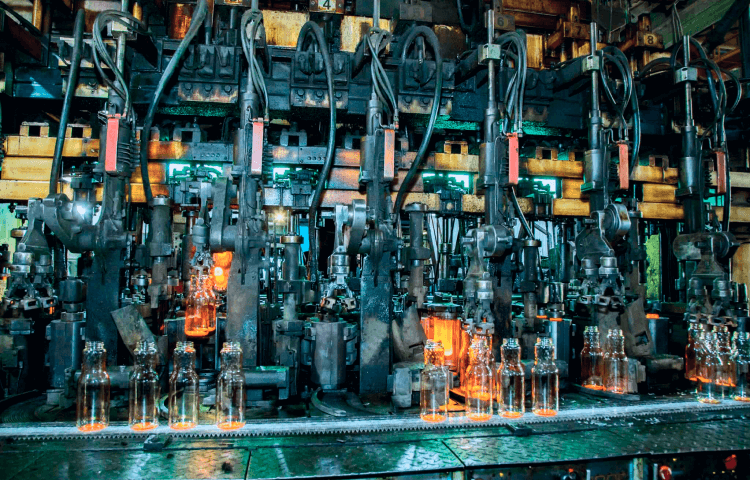

- continuous monitoring at the glass production site;

- periodic control when leaving the annealing furnace;

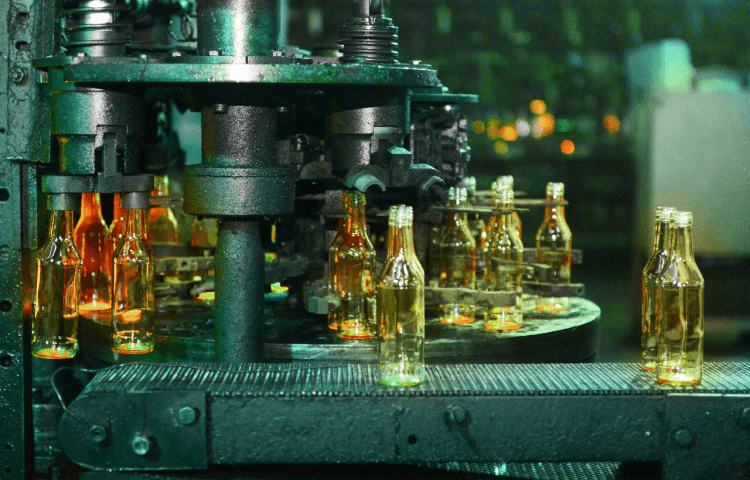

- complete control of appearance and geometric parameters using inspection equipment;

- continuous control of the appearance on light screens;

- acceptance control at the packaging area;

- spot check at the finished goods warehouse.

The plant's specialists have developed and implemented an integrated quality and safety management system that meets the requirements of international standards ISO 9001: 2015 and ISO 22000: 2018, which is confirmed by accredited certification companies.

An integrated quality management system is an integral part of an organization's activity management system and is a set of structure, organization standards, processes and resources, combining all types of activities that affect the quality and safety of products at all stages of production and economic activity.

High-quality raw materials and auxiliary materials, modern technologies, a team of professionals, an ongoing educational process in conjunction with a functioning quality and safety management system is a tool that allows the Stellar Glass to prove its ability to meet the requirements of our customers in the stated volumes. Hide